Advanced outside air controls for packaged rooftop units (RTUs) integrate economizer control with demand control ventilation (DCV).

Economizers increase outside air intake for cooling when outdoor temperature and humidity are favorable, reducing energy use and pollutants generated indoors, including infectious aerosols.

When economizers are inactive, DCV adjusts ventilation to maintain a CO2 setpoint, balancing energy efficiency with indoor air quality.

While economizers save energy and help limit indoor-generated pollutants, they can introduce excessive outdoor pollutants when air quality is poor.

Additionally, past WCEC research found that common DCV control algorithms poorly regulate CO2 levels.

The goal of this research is to develop an improved outside air controller for RTUs that balances occupant exposure to outside air pollution, infectious aerosols, and HVAC energy use. The research aims to model the impact of the controller and test it in a field demonstration of two occupied classrooms with standard RTUs with existing economizers.

Progress

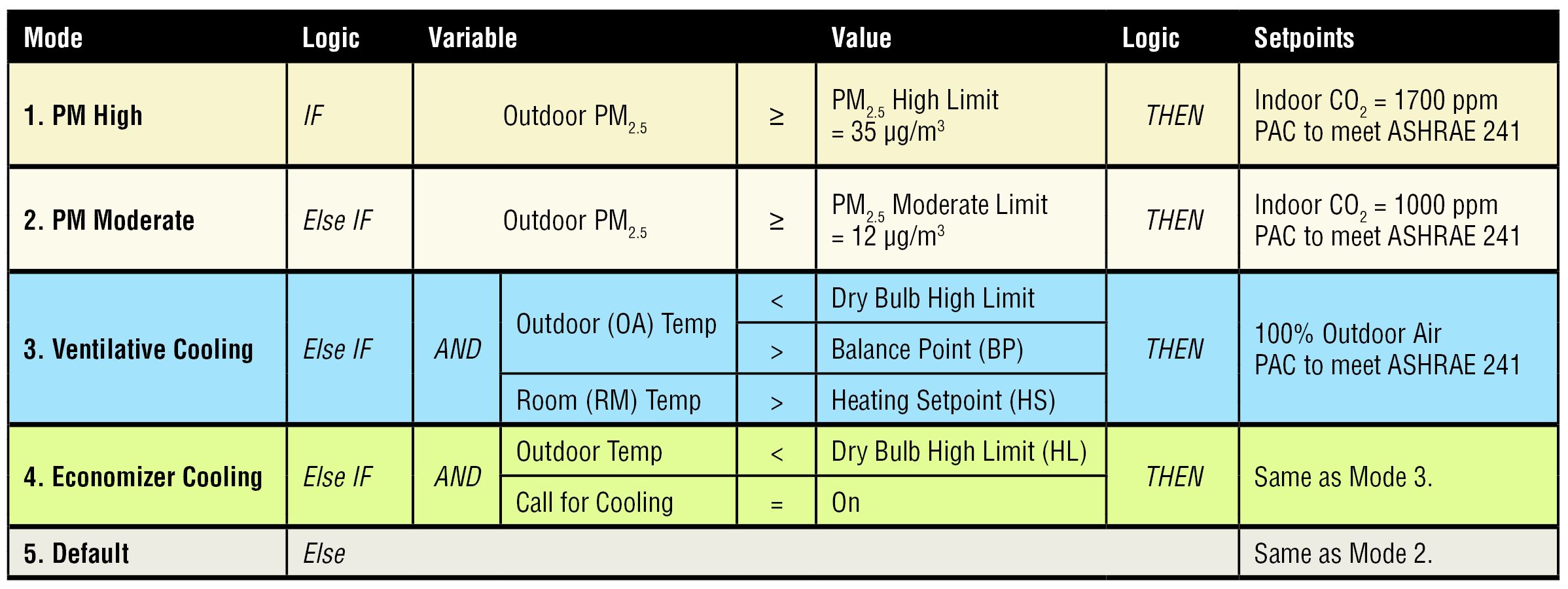

The IAQ-Energy Controller was developed with a straightforward and easy to implement rule-based control logic (Table 1). The IAQ-Energy Controller considers outside fine particulate matter (PM2.5) in its decision making, which is obtained from a sensor installed at the site or over the internet from the closest AirNow monitoring station. The IAQ-Energy Controller also incorporates a ventilative cooling mode, which increases outside air to 100% when outside air conditions are within range, akin to opening the windows on a nice day.

Each controller mode was designed to meet or exceed ASRHAE Standard 241, control of infectious aerosols. When outside air ventilation is reduced in response to poor outside air quality, a portable air cleaner (PAC) is operated to provide equivalent removal rates.

Detailed modeling illustrates the air quality and energy benefits of the IAQ-Energy controller compared to state-of-the-art ventilation systems. The IAQ-Energy Controller reduced electricity use compared to the fixed rate ventilation system in 12 cities (range 5 to 16%, slightly less than the savings from the Economizer + DCV system). The maximum indoor PM2.5 exposure decreased substantially with the IAQ-Energy Controller. On the highest average outdoor PM2.5 day of the year, the IAQ-Energy Controller reduced average PM2.5 indoor exposure in Stockton, San Francisco, and Seattle by 10.8, 19.0, and 24.3 µg/m3, respectively, compared to the Economizer + DCV system. The IAQ-Energy controller also consistently attained ASHRAE Standard 241 for infectious respiratory aerosol removal.

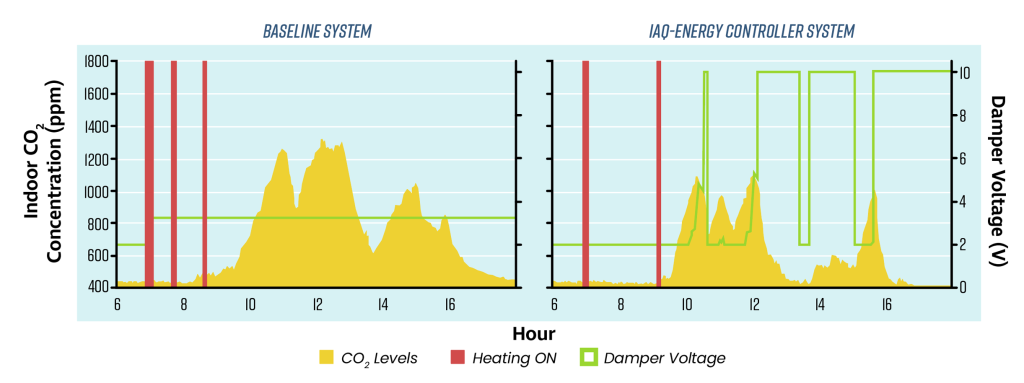

To characterize the performance of the IAQ-Energy controller in a real-word field study, we compared the IAQ-Energy Controller to a fixed rate ventilation approach in side-by-side classrooms at an elementary school in California’s Central Valley over a school year. The study was implemented using two classrooms and a repeated measures crossover design, where the two ventilation interventions (IAQ-Energy controller and fixed rate) alternated weekly between Classroom A and Classroom B. The performance of the two ventilation systems is compared on a winter day with good outdoor air quality in Figure 1. The baseline system (left) ventilates the classroom at a fixed rate all day, resulting in elevated CO2 levels several times during the day. In contrast, the IAQ-Energy controller modulates the outdoor air damper in the morning to maintain a CO2 setpoint of 1000 ppm. When outdoor air temperatures are favorable in the afternoon, the damper opens to 100% outdoor air (10V), further reducing CO2 concentrations without requiring heating or cooling.

Previous Work

- WCEC developed an innovative test method to evaluate commercially available DCV controllers for packaged HVAC systems. The goal was to assess their performance in controlling indoor CO2 levels in response to occupancy patterns. They found that, while some controllers achieved decent performance, most struggled to maintain CO2 levels within the desired range.

- In addition to the published paper, the performance data is available at https://energyproductevaluations.org/, which is a resource developed and led by UC Davis by for obtaining product-specific evaluations for energy-related products.

RESOURCES

Sponsor: Flu Lab

Collaborator: Trane Technologies