Problem

Packaged air conditioning and heating Roof Top Units (RTUs) provide an estimated 75% of the cooling to commercial buildings in California and can account for more than 50% of peak electrical demand.

Solution

Optimizing the efficiency of RTUs can reduce the strain put on the California electric grid from compressor-based cooling.

Goal and Results

2019

This project, funded by Southern California Edison, measured the performance of an emerging technology nominal three-horsepower (3HP) high rotor pole Switched Reluctance Motor (SRM) with software-controlled inverter, compared to a baseline nominal 3HP baseline induction motor controlled by a Variable-Frequency Drive (VFD) in laboratory testing, and a nominal 3HP baseline single-speed induction motor for field testing.

Laboratory Test Approach

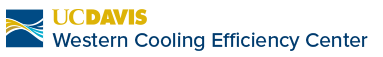

Baseline and emerging technology performance was characterized using two different test setups: 1) a benchtop dynamometer; and 2) a laboratory RTU’s indoor fan. For the benchtop dynamometer testing, each motor/drive was tested over seven different load conditions at six different speeds. For the laboratory RTU, each fan/motor/drive was tested over three fixed-resistance conditions at seven different fan speeds.

Laboratory Results

The benchtop dynamometer and laboratory RTU test results show the high rotor pole SRM with software-controlled inverter is a promising option for reducing fan power, when compared to an equivalent-sized induction motor.

In dynamometer testing, for the seven different load conditions, the high rotor pole SRM used 9.2% to 36.2% less power than the baseline induction motor and VFD system to generate the same torque. In laboratory RTU testing, the high rotor pole SRM reduced the fan power intensity, when retrofitted to the existing belt and fan configuration. On average, the high rotor pole SRM reduced the fan power intensity by 16.9%, 17.5%, and 21.3% for the low, medium, and high-airflow resistance conditions.

Field Testing Approach

Field testing was conducted between November 1, 2017 and August 31, 2018. A field site location in Corona, California was selected for testing, based on previous evaluations performed at that location. Over the test period, the 10-ton RTU was run with the baseline constant-speed fan, then retrofitted with the emerging technology high rotor pole SRM.

The retrofit motor was run in two modes: 1) a constant speed, matching the original baseline motor’s rotational speed; and 2) variable speed, to demonstrate the additional energy savings possible by implementing a variable-speed blower control. Motor power, static pressure between the supply and return ducts, supply airflow, and supply and return air dry bulb and Relative Humidity (RH) were used to compare the performance of the baseline to the emerging technology.

Field Testing Results

During the field test, the baseline motor used 0.94 – 1.21 kilowatts (kW) while operating at 1,725 RPM. At the same operating speed, the high rotor pole SRM used 0.617 – 1.083 kW. On average, it reduced the required power draw by 15% compared to the baseline, and was able to obtain these savings with a power intensity that was, on average, 11.2% lower than the baseline motor.

Operating at variable speed achieved additional savings by reducing the airflow rate when full airflow was not required. During the variable-speed portion of the field test, the high rotor pole SRM used 0.855 kW while operating at 1,294 RPM (75% of full speed) for Stage 1 cooling, and 0.131 kW while operating at 690 RPM (40% of full speed) for air circulation.

Recommendations

Based on the study results, high rotor pole SRMs with software-controlled inverters have the potential to save energy and reduce demand compared to constant-speed induction motors, as well as induction motors controlled by VFDs in RTU indoor fan applications. The savings was achieved though technological differences that allow the high rotor pole SRMs to operate at a higher efficiency over a range of load and speed conditions.

2018

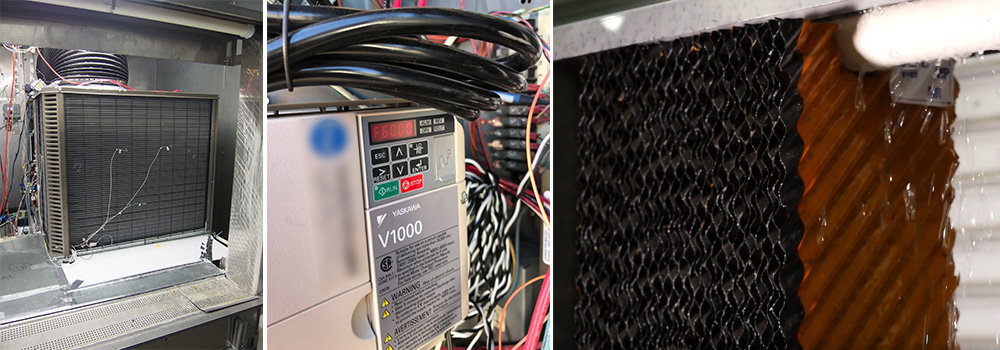

With funding from Southern California Edison, WCEC developed a combined retrofit optimization package that can increase the efficiency of RTUs, reduce peak electrical demand, and maintain net capacity at peak. The optimization package includes a variable frequency drive (VFD) to reduce the compressor speed and a condenser-air pre-cooler. Researchers field tested this package at a big box retail store in Corona, CA. A 10-ton RTU, that served part of the store room, was selected and retrofitted with two VFDs (one for each compressor) and a condenser-air pre-cooler. The performance of the RTU with optimization package was compared to the performance of the same unit without the optimization package.

Field testing illustrated that the combined retrofit package has the potential for significant energy savings. On average, while operating both compressors, the efficiency increased by 23%, the net capacity decreased by 9%, and the power draw decreased by 26%. Additionally, the characteristic performance of the combined retrofit had very little dependence on the outside air temperature. Therefore, the biggest performance improvement was measured at the hottest outdoor air conditions: 33% increase in efficiency, no change in net capacity, and 33% decrease in power use.

Future work should investigate the performance of the combined package on higher capacity RTUs and the impact to RTU performance when only a subset of the available compressors are reduced to 48Hz operation.

Publications and Downloads

- Laboratory Testing of Software-Controlled Switched Reluctance Motors (Case Study, 2019)

- Software-Controlled Switch Reluctance Motorsn (Report, 2019)

- Laboratory and Field Testing of RTU Optimization Package Combining a Condenser-Air Pre-Cooler with Compressor Speed Reduction (Report, 2019)

- Laboratory Testing of Variable Speed Compressor and Fan Controls for RTU Optimization (Report, 2016)

- Evaporative Condenser Air Pre-Coolers (Report, 2016)

- Condenser-Air Pre-Cooler Retrofits (Case Study, 2013)